Horizontal Baler FAQ

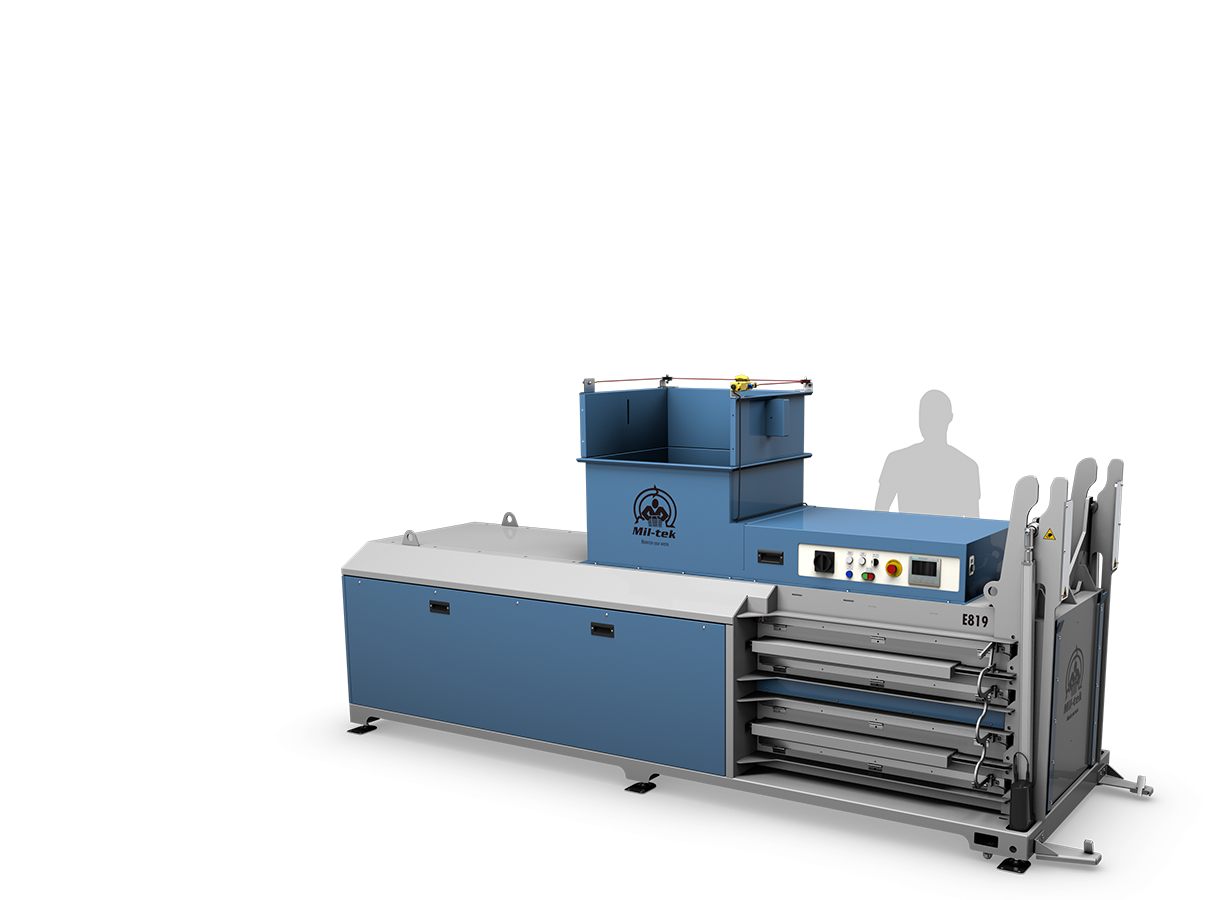

Why should I choose a horizontal baler?

You should choose a horizontal baler if you need to handle large amounts of waste efficiently, want high automation, and require continuous operation with minimal manual effort.

What is the difference between a horizontal baler and a vertical baler?

A horizontal baler compresses materials horizontally and is often fully automatic, while a vertical baler compresses vertically and is typically operated manually or semi-automatically.

How large are the bales produced by a horizontal baler?

The size of bales from a horizontal baler varies depending on the model. The weight can range from 200 kg to over 1 ton, depending on the material and compression strength.

How are bales tied in a horizontal baler?

Bales from a horizontal baler are tied with metal wire or plastic strapping, depending on the machine’s design and level of automation.

What materials can be compressed with a horizontal baler?

Paper, plastic, hard plastic, PET bottles, textiles, and more.

How does automatic operation work on a horizontal baler?

Automatic operation in a horizontal baler means that the machine can handle automatic start upon waste loading, compression, and bale ejection without constant manual supervision.