Lean auto efficiency helping Jaguar Land Rover toward net-zero emissions goal

The volume of waste is reduced and the overall amount of waste being sent to landfill has seen a significant decrease while the level of recycling has risen exponentially.

Jaguar Land Rover increases available electrical charging points

Jaguar Land Rover has been enjoying the many benefits of partnering with Mil-tek to better optimise its waste handling.

And as a bonus, removing the skip has allowed them to more than double the number of charging points for electric vehicles.

Watch the video

For over 60 years, Jaguar Land Rover Ribblesdale has been servicing and selling vehicles to happy customers. A need to improve their waste handling processes was identified by a key team member and they contacted the team at Mil-tek for their guidance.

Traditionally, the facility had a large open skip container at the back of the building for all waste and refuse. Technicians typically walked around to the back of the building and deposited the waste in the skip, an inefficient process that was time-consuming and unsustainable. The skip itself was open, subject to the elements, took up a large amount of space and was generally unsightly. Watch the video to learn more.

Walking the waste

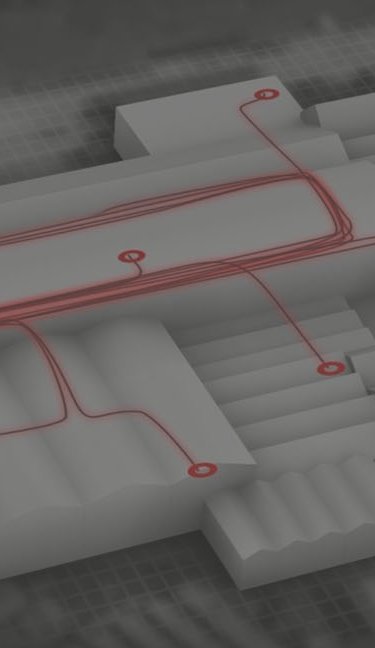

Walking the waste was identified as a source of inefficiency for the technical staff. Mil-tek proposed removing the skip entirely and placing multiple air-powered solutions within the workshop area.

Placing solutions close to the technicians in this way would increase their efficiency and also minimize the amount of space dedicated to waste. This was made possible by the fact that the machines installed are all pneumatically powered meaning they could be easily and quickly installed in tight locations close to where technicians are working.

Efficiency improvements

Putting the machines close to the operational and working areas proved to be a key factor in increasing the efficiency of the technical staff. One Technician was measured to have improved by 7% since the introduction of Mil-tek, meaning a significant increase in his invoiceable hours.

Across the board, the team measured an average increase of between 3-5%, putting a real and quantifiable number on the savings and improvement that has come from the Mil-tek solution.

Waste volume reduction

Minimizing waste was the goal of the project and, over and above the additional benefits discovered by introducing the solution, the goals have been met. By installing the solutions so close to the working environment, the team are naturally inclined to put recyclable material into the baler and non-recyclable material into the compactor.

In both instances, the volume of waste is reduced and the overall amount of waste being sent to landfill has seen a significant decrease while the level of recycling has risen exponentially.

Have a question?

Get in touch today to learn more about how Mil-tek can help your business save time, space and money by better handling waste

Get info about a product or have a chat with one of our local reps. Let us know what you need so the right person can get in touch